Sludge Dewatering: Efficient Solutions for Every Application

During wastewater treatment, sludge is produced—a mixture of water and solid particles. To reduce its volume, lower transport costs, and simplify further processing, this sludge must be dewatered. Taneco provides advanced systems that make this process reliable, energy-efficient, and cost-effective.

Several technologies exist for sludge dewatering. Below, we explain the belt filter press, decanter centrifuge, chamber filter press, and screw press, and highlight when each technology is the best fit.

Belt Filter Press – Continuous Dewatering with High Throughput

A belt filter press is a mechanical dewatering system that operates continuously. The sludge is first thickened and then evenly applied onto a moving filter belt. As it passes between two belts, it is gradually compressed by a series of rollers. Water drains through the belts, while the dewatered sludge exits as a firm, uniform cake.

Advantages

- Continuous operation, ideal for high sludge volumes

- Low energy consumption and low maintenance costs

- Easy to operate

- Suitable for many sludge types, especially biological sludge

Best Used When

High throughput, low operational costs, and a robust solution are required. Common in municipalities, industry, and the food sector.

Decanter Centrifuge – Fast Dewatering with High Separation Efficiency

A decanter centrifuge uses centrifugal force to separate water and solids. The sludge is fed into a rapidly rotating horizontal bowl. The intense G-forces push the solids outward, where they are conveyed and discharged, while the clarified water flows out separately.

Advantages

- Compact and fully enclosed system

- Achieves high dry solids content

- Handles thin sludge and variable feed rates well

- Hygienic operation with minimal odor or spillage

- Fully automatic operation

Best Used When

Flexibility, automation, and hygiene are essential. Widely used in industrial processes, petrochemicals, food production, and municipal facilities.

Chamber Filter Press – Maximum Dewatering for the Driest Cake

A chamber filter press consists of several filter plates that form chambers filled with sludge. Under high pressure, water is forced through the filter cloths, leaving behind a very dry, solid sludge cake.

Advantages

- Highest achievable dry solids content of all technologies

- Extremely robust, suitable for hard-to-dewater sludges

- Low operational costs when used in batch processes

Best Used When

Maximum dewatering is required, especially for sludge with high disposal costs or sludge that is difficult to separate from water.

Screw Press – Energy-Efficient and Low-Maintenance Dewatering

A screw press dewaters sludge using a slowly rotating screw inside a perforated cylinder. As the sludge moves along the screw, it is gradually compressed while the water drains through the openings. The slow speed minimizes wear and energy use.

Advantages

- Very low energy consumption

- Minimal maintenance due to low rotational speed

- Compact design and quiet operation

- Suitable for biological and mixed sludges

- Fully automatic, continuous process

Best Used When

Energy efficiency, low maintenance, and a compact installation are important. Common in municipal treatment plants and the food industry.

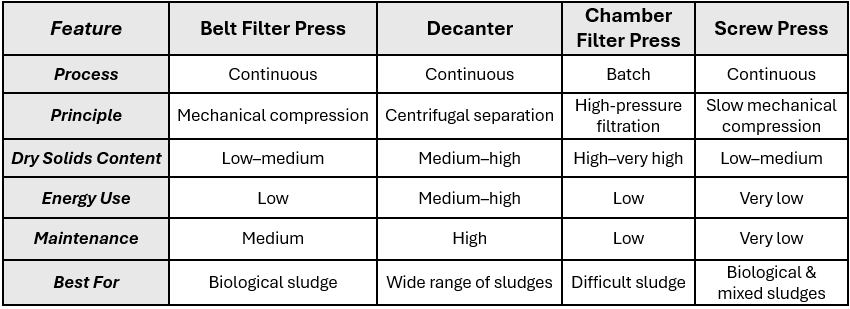

What Are the Differences?

Which Solution Is Right for You?

Every application has its own requirements. Taneco provides tailored advice to determine the ideal dewatering technology based on:

- Sludge characteristics

- Required dry solids percentage

- Processing capacity

- Available space

- Energy consumption

- Desired level of automation

Our specialists help you strike the perfect balance between cost, performance, and reliability.