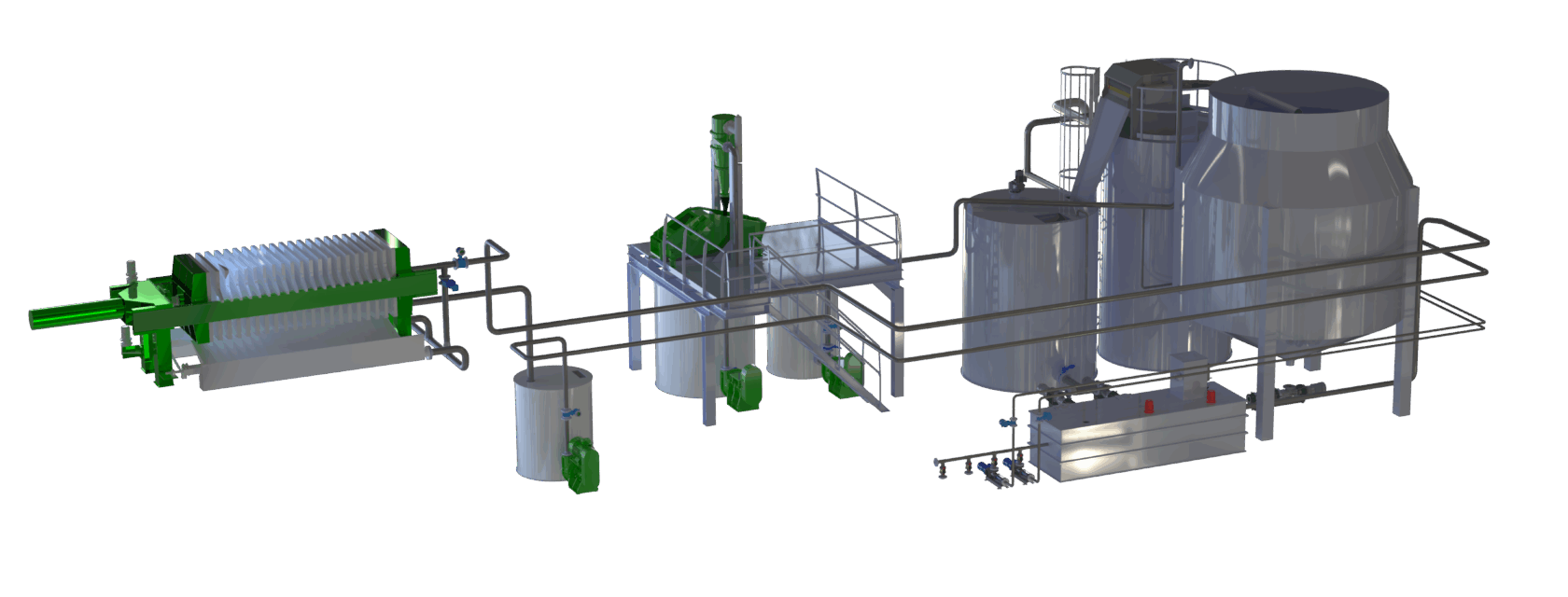

AGRO WWT 100: Turn-Key Wash-Water Treatment for Large Fresh-Produce Processors

The AGRO WWT 100 is Taneco’s fully customer-specific, turn-key Waste Water Treatment installation for large potato and vegetable processing companies.

Each WWT100 line is designed based on the required process flow, the available space, and the customer’s specific operational needs. If necessary, multiple lines can be combined to achieve very high production capacities.

Capacity & Engineering of the AGRO WWT 100

- Capacity fully tailored to customer requirements

- Custom layout, component selection, and process configuration

- Scalable for extremely large production flows

- Ideal for 24/7 production environments in the fresh-produce sector

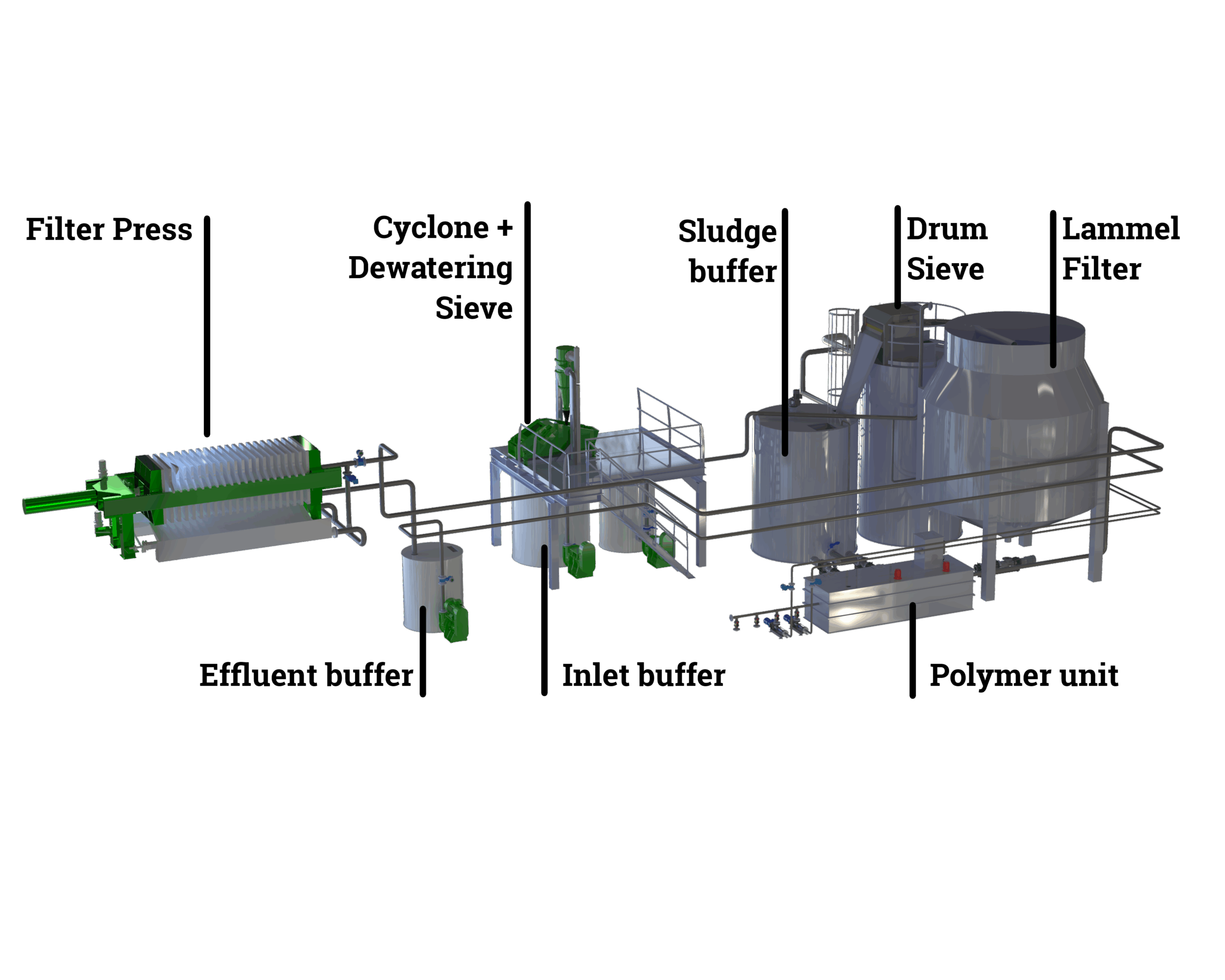

The Process: From Sand Separation to Reusable Wash Water

Sand Separation

The process begins with the removal of sand. The incoming wash water flows from a receiving buffer to a Linatex-lined pump, which feeds the water through a Linatex cyclone.

Here, sand down to 50 microns is separated and then mechanically dewatered to approx. 80% dry matter.

Sludge Separation

Depending on the pollution load, polymer is added to achieve optimal flocculation.

For sludge thickening, the customer can choose between:

- Belt thickener – for continuous thickening

- Lamella separator – compact, high capacity, very efficient

Sludge Dewatering

For the final sludge dewatering process, there are two options:

- Chamber filter press – batch-wise, very high dry-solids content

- Decanter – continuous processing, stable and automatic

Reuse of Wash Water

After all separation steps, the AGRO WWT 100 delivers clear, purified, and reusable wash water, enabling up to 95% water savings, even in continuous operation.

Automation & Software

Taneco can supply the complete electrical installation and develops custom PLC software for both simple and complex lines.

Features include:

- Remote monitoring

- Remote service and support

- Centralized control of multiple parallel WWT100 installations

Fully integrated process automation.

Benefits Taneco

WWT 100

- Designed and produced based on customer requirements.

- Maximum results with minimal use of polymer, water and energy

- One single supplier for delivery of the entire installation.

- Excellent service and operational support.

- CE marking on the whole system.