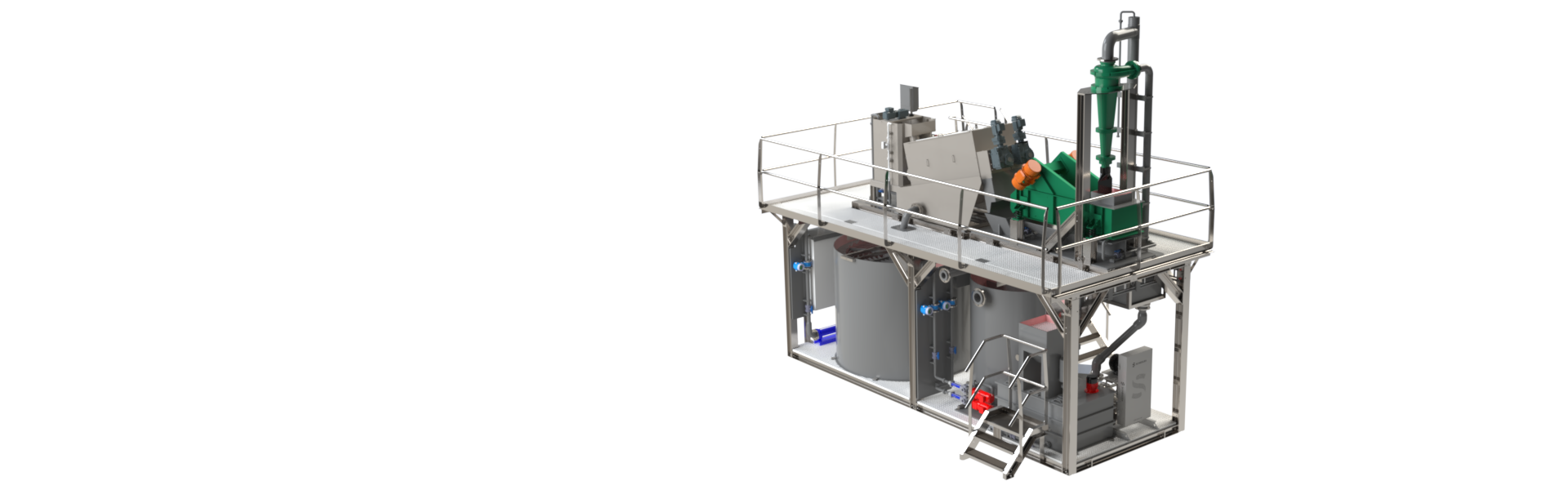

AGRO WWT 50: Compact and Efficient Wash-Water Recycling for Fresh-Produce Processors

Taneco offers the ideal solution for potato and vegetable processors looking to recycle their wash water in a simple, compact, and cost-effective way. The Taneco AGRO WWT 50 installation treats wash water and achieves water savings of up to 95%.

The installation can process water flows of up to 50 m³/hour, originating from the washing of potatoes or vegetables. The system is built on two stacked skids, requiring less than 20 m² of floor space.

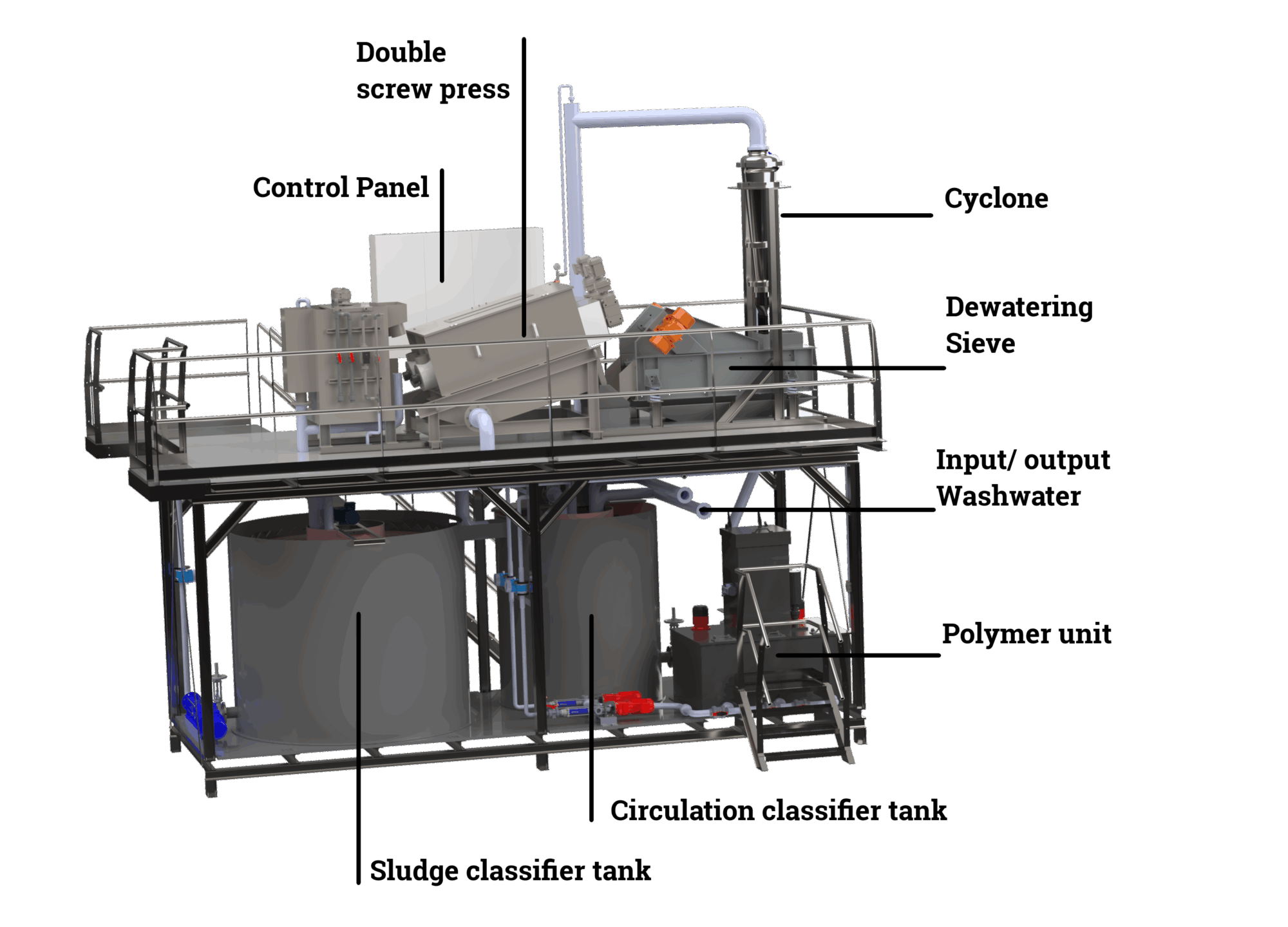

Configuration of the Taneco AGRO WWT 50

The installation consists of the following main components:

- Circulation classifier

- Sand recovery system

- Sludge classifier

- Sludge dewatering system

The Process: Efficient and Fully Automated

Inlet and Sand Separation

The unit is equipped with connections for wash-water intake, discharge, and clean-water supply.

The wash water enters through the circulation classifier, where sand settles out of the flow.

Sand Recovery (Hydrocyclones)

The settled sand is pumped to the sand recovery system.

Using hydrocyclones, solid particles down to 25 microns are separated.

The dewatering screen dewaters these particles to a dry-matter content of approximately 75%.

Sludge Separation

The de-sanded water then flows into the sludge classifier.

With the addition of a small amount of polymer, sludge particles settle quickly and efficiently.

Sludge Dewatering and Water Return

The sludge dewatering system separates the sludge fraction from the water.

The cleaned water flows back to the washers, while sand and sludge are discharged by a conveyor belt.

Benefits Taneco WWT 50

-

turn-key solution with capacities up to

50 m³/h - Plug & Play system

- Low investment costs

- Small footprint

- CE certification